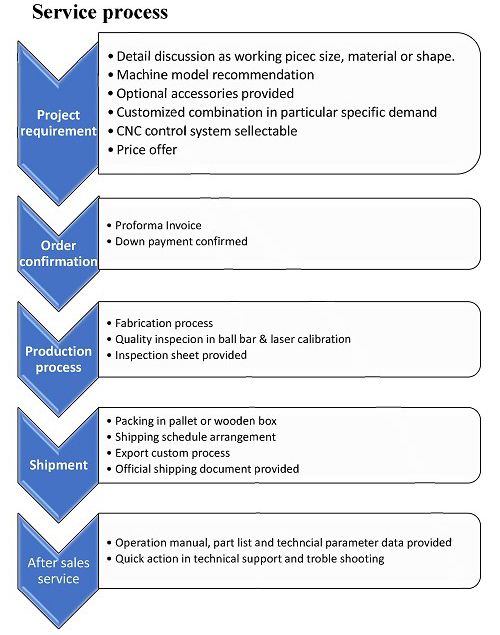

Service Process

A completely service from GSM offers not only including the initial discussion and price offer, but also supports to multiple accessories and well after-sales service.

Fabrication Process

- Cast Iron: We commission casting factories in Taiwan to produce castings of the wooden molds designed by GENG-SHUEN CO., LTD. After annealing, the castings become suitable for further processing.

- Milling Process: Using Double Column Machining Center, the castings are milled to create the flat surfaces, grooves, and holes according to GENG-SHUEN CO., LTD design drawings.

- Heat Treatment: As GENG-SHUEN CO., LT's machines is design by box way, the heat treatment of the box ways is a crucial step. After heat treatment, the box ways exhibit higher hardness and durability.

- Grinding: Grinding is performed to make the heat-treated rails smooth and precise.

- Stick Turcite-B (Made in Germany): Turcite-B is a high-performance polymer material. GENG-SHUEN CO., LTD specifically selects German-made Turcite-B to provide wear resistance and improved lubrication on the mating surfaces (box way) of mechanical components.

- Scraping: GENG-SHUEN CO., LTD employs experienced craftsmen with over 40 years of expertise to scraping the castings. This ensures the average contact area and accuracy of the mating surfaces.

- Spray-painting: After filling, the castings are painted to maintain a smooth exterior and it will paint to meet various customer color requirements.

- Assembly: The castings are assembled by comparing their flatness and perpendicularity. Precision is verified using ball- screw test rods.

- Ball Screw Accuracy Calibration: After checking by the Ball screw test rods, the castings are fitted with ball- screw and their accuracy is repeatedly checked.

- Metal Plate Assembly: Assembly is performed based on the selected machine accessories. Whether it is a half-enclosure or full-enclosure, the assembly includes drilling holes on casting to ensure completeness.

- Electrical Distribution: After the three axes of the machine are completed, the controller which been selected is installed to achieve machine control. This includes cable routing, wiring, and parameter adjustments.

- Pilot Run: After electrical installation is completed, the machine testing by a box way runing to ensure the compatibility between the electrical control and mechanical aspects. This allows for parameter adjustments and ensures the machine mechanism compliant GENG-SHUEN CO., LTD standard.

- Machine Inspection: This includes quality inspections, laser testing, ball bar checking, and the optional accessories electrical tests.

- Packing: When the machine has completed all tests and is ready to leave the factory, it will be packaged again. Depending on the packaging method, there are plates or wooden boxes.

- Shipment: Goods are shipped according to customer instructions and trade terms (FOB, EXW, CFR).